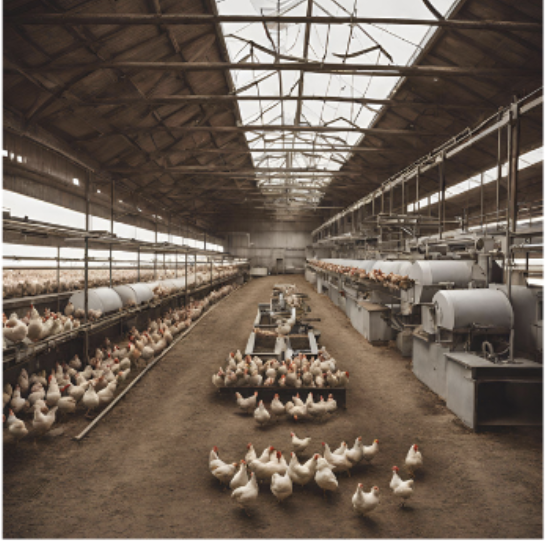

Stepping into the dynamic world of poultry farming reveals a bustling environment where the lively sounds of poultry coexist harmoniously with the constant hum of machinery, creating a unique agricultural symphony. While the birds undoubtedly play a starring role in this production, it is the robust equipment that truly ensures the smooth running of operations, but beneath the surface of efficiency and productivity lies a critical challenge: the relentless strain placed on machinery, leading to potential breakdowns and expensive repairs.

In this blog, the pivotal role of proper lubrication is highlighted, demonstrating how this seemingly simple practice is crucial for the longevity and optimal performance of farm equipment. By embracing the power of lubrication, farmers can elevate their operations, ensuring that every piece of machinery operates seamlessly, contributing to a prosperous and sustainable farming venture.

The Importance of Keeping Your Equipment Well-lubricated

Keeping your equipment well-lubricated is essential for maintaining smooth operations on poultry farms. The constant use and heavy workloads put a significant strain on your machinery, leading to potential breakdowns and costly repairs. That’s why proper lubrication is crucial.

Lubricants, such as oil and grease, help reduce friction and wear on moving parts, allowing your equipment to operate smoothly. Without sufficient lubrication, components can become damaged, leading to mechanical slowdowns and increased downtime. This not only affects productivity but also increases the risk of costly equipment failure.

Regularly applying lubricants to your machinery helps prevent overheating and reduces the chances of costly repairs. By keeping your equipment well-lubricated, you can extend its lifespan and maximize its efficiency, ultimately saving you time and money.

Pay attention to the importance of proper lubrication on your poultry farm. Take the necessary steps to ensure your machinery is well-maintained and lubricated to keep operations running smoothly and avoid any unnecessary downtime or expenses.

Best Practices for Minimizing Equipment Downtime on Poultry Farms

When it comes to minimizing equipment downtime on poultry farms, implementing best practices is essential. A publication by the Virginia Cooperative Extension at Virginia Tech University notes that farmers reduce maintenance costs by 25% after improving their maintenance procedures. The article uses an example of an $80,000 tractor that typically requires about $24,000 in repair costs during 5,000 hours of operation when receiving average maintenance. This cost can be decreased to approximately $18,000 with proper service management.

Among the critical factors to consider is proper maintenance and inspection. Regularly check your machinery for signs of wear and tear, and address any issues promptly. This proactive approach can help identify problems before they lead to breakdowns and costly repairs.

Additionally, developing a comprehensive maintenance schedule is crucial. This includes regular oil changes, filter replacements, and lubrication of moving parts. Keeping track of maintenance tasks and scheduling can significantly reduce the risk of equipment failures.

Another important aspect is training your staff on proper equipment usage and maintenance. By educating your team on best practices and ensuring they understand how to operate and care for the machinery correctly, you can minimize the risk of human error and equipment damage.

A Detailed Guide to Fuel Management for Efficient Farm Operations

Efficient fuel management is crucial for ensuring smooth and cost-effective operations on poultry farms. It’s essential to have a detailed guide to help you effectively manage fuel consumption and minimize costs.

Here are some key strategies to consider:

- Monitor fuel usage: Keep track of fuel consumption for each piece of equipment. This will help you identify anomalies or inefficiencies and take necessary actions to optimize fuel usage.

- Plan routes and schedules: Plan the most efficient routes for your vehicles and equipment to minimize unnecessary fuel consumption. Consolidate tasks to reduce travel time and fuel usage.

- Use fuel-efficient equipment: Invest in fuel-efficient vehicles and machinery. Look for models with advanced engine technology that can reduce fuel consumption without sacrificing performance.

- Regular maintenance: Maintain your equipment correctly to ensure optimal fuel efficiency. Regularly check and clean filters, inspect tires for proper inflation, and keep engines tuned.

- Driver training: Train your drivers on fuel-efficient driving techniques, such as avoiding rapid acceleration and braking and maintaining a consistent speed. This can significantly reduce fuel consumption.

Choosing the Right Lubricant: A Major Step in Maintaining Poultry Farm Equipment

Selecting the proper lubricants for your poultry farm equipment is a significant step toward maintaining smooth operations and minimizing downtime. With so many options available in the market, it can be overwhelming to determine which lubricant is best suited for your specific needs. However, taking the time to make an informed decision can benefit your farm in the long run.

When choosing a lubricant, it’s essential to consider factors such as temperature, load, and application method. Different types of equipment may require other lubricants, so it’s crucial to consult the manufacturer’s recommendations or seek expert advice. Additionally, considering the environmental impact and sustainability of the lubricant can align with your farm’s values.

Furthermore, regular oil analysis and monitoring can help ensure that the lubricant performs optimally and identifies potential issues early on. By choosing the right lubricants for your poultry farm equipment, you can enhance the efficiency and lifespan of your machinery, ultimately saving time and money in the process.

For more information on proper lubrication for your farm or poultry operation, contact one of our experts.